3M Novec7500 Electronic fluorination solution Cas 297730-93-9

Introduction

3M™ Novec™ 7500 Engineered Fluid is a nonflammable fluid with very low global warming potential for

use in heat transfer applications. Novec 7500 fluid shares many of the inertness and dielectric properties of

perfluorocarbons (PFCs) and perfluoropolyethers (PFPEs), and is a viable option for replacing them in a wide

array of applications

Semiconductor

This Novec fluid can be used in cooling of ion implanters, dry etchers and CVD machines in semiconductor and

flat panel display manufacturing facilities.

Test Equipment

The fluid may be used to cool semiconductor thermal shock and test equipment.

Electronic Cooling

Because Novec 7500 fluid is compatible with most electronic components, it can be used in direct contact

single- and two-phase cooling of supercomputers and sensitive military electronics, and to cool high voltage

transformers and power electronics.

Industrial/Pharmaceutical

Novec 7500 fluid can also be used as an alternative to commonly used fluids in pharmaceutical and chemical

manufacturing processes, such as freeze drying and reactor cooling.

The primary advantage of Novec 7500 fluid over a comparable PFC or PFPE, however, is reduced Global

Warming Potential (GWP). Novec 7500 fluid has been developed as a low-GWP alternative to perfluorocarbon

and perfluoropolyether heat transfer liquids.

Novec 7500 fluid is non-ozone-depleting and has been exempted from the U.S. EPA definition of a volatile

organic compound (VOC) because it does not contribute to the formation of photochemical smog

Typical Physical Properties

| Properties |

3M™ Novec™ 7500 Engineered Fluid |

| Boiling Point @ 1 atm (°C) |

128 |

| Pour Point (°C) |

-100 |

| Molecular Weight |

414 |

| Liquid Density (kg/m3) |

1614 |

| Coefficient of Expansion |

0.00129 K-1 |

| Latent Heat of Vaporization @ 1 atm. (kJ/kg) |

88.5 |

| Surface Tension (dynes/cm) |

16.2 |

| Viscosity (cSt) |

0.77 |

| Critical Temperature (°C) |

261 |

| Critical Pressure (Mpa) |

1.55 |

| Solubility of Fluid in Water |

<3 ppm by weight |

| Dielectric Strength |

35 kV, 0.1" gap |

| Volume Resistivity |

2.2x108ohm-cm |

| Dielectric Constant |

5.8 |

| Flammability |

Nonflammable |

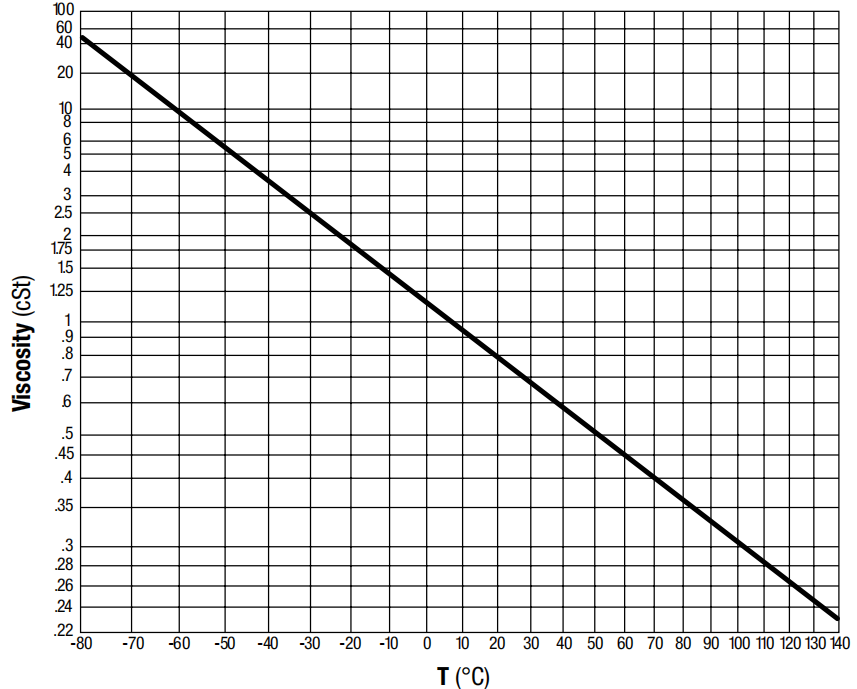

Novec 7500 Fluid Kinematic Viscosity

To determine the viscosity at a given temperature T in Kelvin, calculate

Z = 10^( 10^( 11.843-5.0874*Log(T[K]) ) ).

Then, Viscosity [cSt] = (Z-0.7) - exp(-0.7487 - 3.295(Z-0.7)

+ 0.6119(Z-0.7)2

- 0.3193(Z-0.7)3 )

Typical Physical Properties (continued)

Typical Physical Properties (continued)

Toxicity Profile

The toxicological testing completed on 3M™ Novec™ 7500 Engineered Fluid indicates very low overall toxicity.

The material is minimally irritating to the skin and eyes and tested negative in two mutagenicity screens.

In its intended applications a large margin of safety exists between anticipated exposure and the eight hour

time weighted average exposure guideline of 100 ppm. In a 28-day oral toxicity study no adverse effects were

observed at 1000 mg per kg body weight.

Toxicological Test Results

| Properties |

3M™ Novec™ 7500 Engineered Fluid |

| Oral LD50 |

>200 mg/kg |

| Acute lethal inhalation concentration |

>10,000 ppm (6 hour) |

| Eye irritation |

Minimally irritating |

| Skin irritation |

Non-irritating |

| Dermal sensitization |

Negative |

| Mutagenicity |

Negative in the two assays conducted |

| Ecotoxicity |

Very low aquatic toxicity |

| 28-day oral toxicity |

NOAEL 1000 mg/kg |

Environmental Properties

| Properties |

3M™ Novec™ 7500 Engineered Fluid |

| Ozone Depletion Potential1(ODP) |

0.0 |

| Global Warming Potential2(GWP) |

90 |

| Atmospheric Lifetime (years) |

2.2 |

| Volatile Organic Compound (VOC) |

No |

1CFC-11 = 1.0

2 GWP = pounds equivalent CO2, 100-year integrated time horizon (ITH), IPCC 2001 method.

Environmental, Health and Safety

Before using this product, please read the current product Material Safety Data Sheet (available through your

3M sales or technical service representative) and the precautionary statement on the product package. Follow

all applicable precautions and directions. 3M™ Novec™ 7500 Engineered Fluid is nonflammable and does not

exhibit flammability characteristics under normal operation and storage conditions. The fluid is resistant to

thermal breakdown and hydrolysis during storage and use. Recommended handling procedures are provided in

the Material Safety Data Sheet, which is available from your local 3M representative upon request.

Materials Compatibility

In practice, Novec engineered fluids differ somewhat from PFCs and PFPEs in their ability to dissolve certain

oils. This means that Novec 7500 fluid is more likely to extract plasticizers from elastomeric materials. For

this reason, elastomeric O-ring and seal materials should be limited to those that contains a low amount of

plasticizer. EPDM, EPR and butyl typically fall into this category. 3M engineers can suggest appropriate

compounds or assist with test procedures.

Heater Selection

The critical heat flux of Novec 7500 fluid was found to be 18 W/cm2

when boiling from a horizontal 0.5 mm

diameter platinum wire in a quiescent pool of saturated fluid. The maximum heat flux obtainable in forced

convection applications is significantly higher, but depends strongly upon the geometry and flow conditions.

A safety interlock between the pump and heater is strongly recommended in applications with heat fluxes

exceeding 15 W/cm2

.

Regulatory Status

The components of this product are in compliance with the chemical notification requirements of the

United States (TSCA), Europe (ELINCS), Korea and the Philippines. Novec 7500 fluid is not acceptable for

commercial sale in Japan. Certain restrictions apply. Contact the selling division for additional information.

Contact your local 3M representative regarding the regulatory status of Novec 7500 fluid in other countries.

Recycle and Disposal Options

Used Fluid Return Program

3M offers a program for free pickup and return of used 3M specialty fluids in the U.S. A pre-negotiated

handling agreement between users and our authorized service provider offers users broad protection against

future liability for used 3M product. The fluid return program is covered by independent third-party financial

and environmental audits of treatment, storage and disposal facilities. Necessary documentation is provided.

A minimum of 30 gallons of used 3M specialty fluid is required for participation in this free program.

For additional information on the 3M Used Fluid Return Program, contact your local 3M representative or call

3M Customer Service at 800.810.8513.

Resources

3M™ Novec™ Engineered Fluids are supported by global sales, technical and customer service resources,

with technical service laboratories in the U.S., Europe, Japan, Latin America and Southeast Asia. Users

benefit from 3M’s broad technology base and continuing attention to product development, performance,

safety and environmental issues. For additional technical information on 3M™ Novec™ 7500 Engineered

Fluid in the United States or for the name of a local authorized distributor, call 3M Electronics Markets

Materials Division: 800 810 8513.